With more than 10 years of D & R and Manufacturing experience, GS METAL produces more than 50 kinds of Titanium Alloy Grades with properties of higher or lower Temperature, burn resistance, high strength or toughness, damage tolerance, resistance to corrosion, etc. and can meet the requirements for applications of aerospace, military, shipbuilding, weapon, chemistry, metallurgy, mechanical, electron, energy, medical and light industries, our company strives to bring high quality and low-costs metals products to market in the most direct and costs effective way. Most high-level titanium alloy grades can be used in extreme environments and can accept the custom’s sensitive tests. We will use flexible methods to serve customers from all over the world. Our advanced equipment supports us to have the better capability as well as quality control.

Related Equipments will be listed below:

Production equipment

- 10kg~15tons VAR Melting

- 50Tons~4500Tons Free and Precise Forging Oil-press

- 800℃~1150℃ Heat Treatment Oven

- Rolling Machine

- Drawing Machine

- Grinding Machine

Test equipment

Chemical composition analysis & Physical Properties of our Titanium mill products will be tested by the Qualified CNAS Approved Quality Inspection Center of Northwestern Institute and BAOTI research center; We are also an ISO9001:2015 & AS9100D as well as ISO13485 approved company certified by France Bureau veritas, and have a VERY stricter internal Quality Control system and the final products can be used in Military & Defense, Orthopedic implant, Aerospace as well as other industrial application.

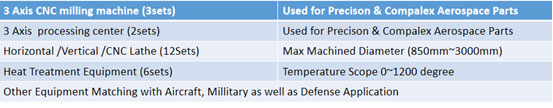

In order to support and help the customer, we also can have advanced process equipment as follows: